EA Pigments »

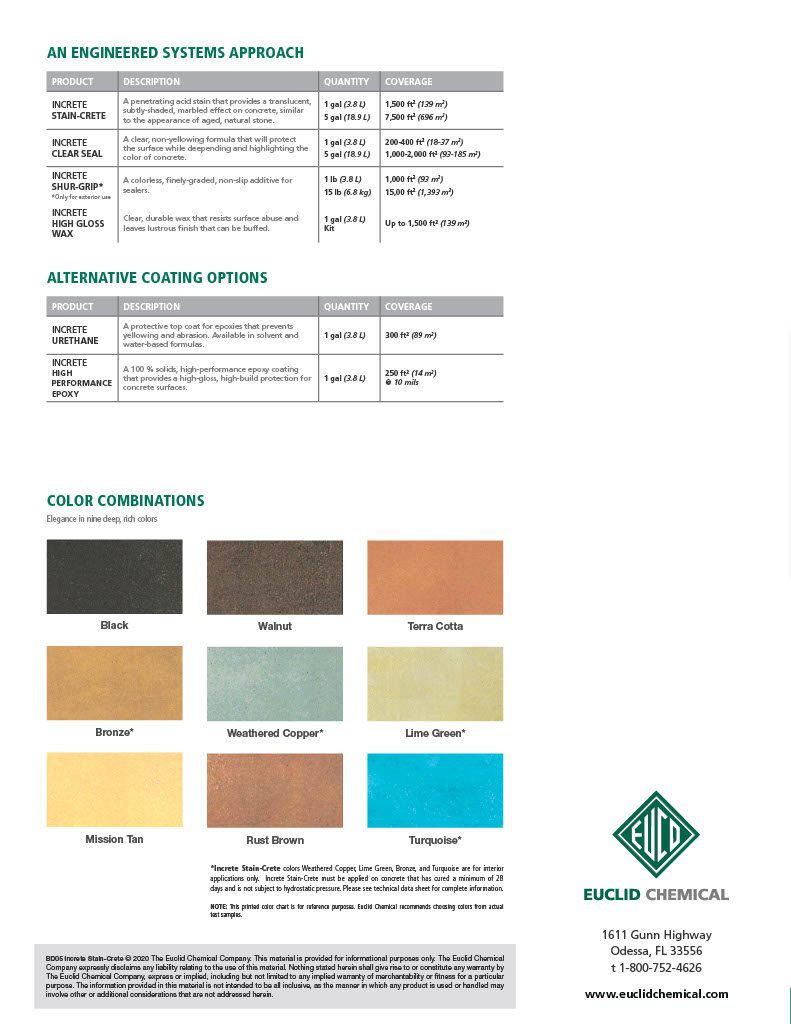

Color Charts

The colors shown are the most popular shades available in granular and powder forms. They do not represent all the colors that can be produced. The color is packaged in disintegrating bags for use in ready-mix concrete. This color chart is to be used as a guideline only.

We recommend that a mockup be poured and approved prior to the start of the job. Our pigments are known for their high tinting strength and consistency.

Benefits

The chief advantage of integral pigments is that the color extends throughout the entire concrete slab, so even if surface abrasion occurs, the color will not wear away. The pigments in integral coloring admixtures are also chemically stable and won’t fade over time from exposure to the weather or ultraviolet light.

Materials

All pigments are permanent, light-fast, inert, and stable to atmospheric conditions. EA Pigments colors comply with ASTM C979. Our colors do not contain any fillers or extenders.

Mix Design

Make sure to use the same mix design and consistent water-to-cement ratio throughout the job with a consistent slump between 4″ to 6″. Color variation may occur if batch proportion and slump are not maintained from load to load. Keep all raw materials (sand, cement, and aggregates) as consistent as possible throughout the entire project. Changes in raw materials (size, color, and moisture content) affect the final color. Remember, water has a vast effect on the final color. Adding too much water will lighten the color of the project, giving it a pale or washed-out look. When better flow ability is required, use a plasticizer or water-reducing admixture. Calcium chloride or any chloride-based accelerator should not be used. Chloride-based additives will cause discoloration in the finished project.

Installation

The pigment is introduced directly into the concrete truck, where it is evenly distributed throughout the entire batch of concrete as the mixing drum rotates. This process ensures that the entire concrete element is uniformly colored. The pigment is premeasured into self-disintegrating paper bags, allowing for easy and accurate pigment addition on the job site or at the ready-mix plant. Generally, the color is packaged at a ratio of one bag of color per one cubic yard of concrete.

Proper Curing

The proper curing of concrete is important to reduce surface shrinkage and cracking and obtain the proper strength. Inadequate curing can result in irregular coloration and the occurrence of efflorescence. It is crucial to employ chemical curing methods for concrete. The practice of water curing or surface covering is not recommended.